Our energy grid was built around centralization. But as renewable energy sources such as solar and wind gain traction, the grid needs to adapt to include an array of components.

“With the decrease in cost of elements such as solar panels and batteries, we, as a society, have begun a move toward a more decentralized structure of energy generation and storage,” explains Francisco Morocz, CEO and Co-founder of Heila Technologies.

That’s where microgrids come in. Microgrids are smaller networks that use local energy sources. They’re typically connected to the grid and can rely on its energy if necessary, but can also run independently in “island” mode.

For microgrids to work with the larger grid, communication is key, as utilities need to navigate peak times and potential disruptions to ensure electricity is always available.

“People started putting up solar panels because they wanted local, renewable, and cleaner energy—and that is great, but their intermittent nature has also been quite disruptive, because now the utility is losing revenue at certain times of the day, but they still have to keep up with the ups and downs of intermittent generation,” Morocz says. “So, you still must have part of the grid infrastructure kind of running in idle, just waiting for when a cloud passes by so you can provide power to the customers when needed.”

Communication benefits both the microgrid and the utility company. A microgrid can rely on the larger grid for energy when it must, but at other times it can support the grid by setting the import or export of power according to the needs of the system.

Traditionally, the monitoring, control, and communications needed for this type of behavior are expensive and difficult to set up and need to be altered with each new component. These roadblocks have slowed down the adoption of microgrids.

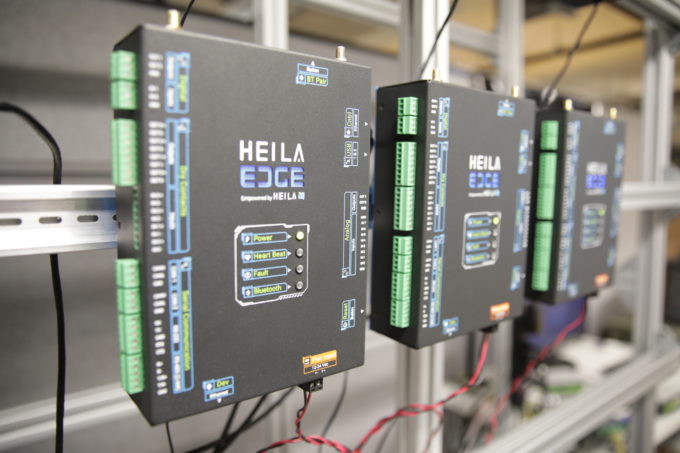

Heila Technologies, however, has created a platform that simplifies this process. A Heila device is installed in each energy asset and allows them to be used by either a site controller, a utility ADMS, or both.

With Heila’s technology, the microgrid doesn’t have to be cohesive, like a system of assets set up and owned by one person. This is especially important as putting solar panels on individual homes continues to increase in popularity. If four homes each had solar panels and batteries installed, a Heila device deployed at each house would turn them into what Morocz calls a “virtual” microgrid. This setup is appealing to utility companies and has the potential to become widespread.

“The grid can better handle large fleets of distributed assets, people get resilient systems that are cleaner, so everybody wins,” Morocz explains.

The Heila team first dreamed up the device when one of its co-founders was installing a microgrid at Stone Edge Farm in California wine country in 2015. The Heila-enabled microgrid is now fully functional, and Heila has four additional projects with private entities and utilities.

The next stage for Heila is scaling up; in 2020, Heila aims to work with utility companies to reach large percentages of their customers.

In the future, Heila’s technology could enable energy selling or trading among neighbors. For instance, if one person has solar panels and storage (which provide energy during the day) and their neighbor has wind turbines and storage (which typically gather the most energy at night), they could swap energy. This type of relationship would require regulatory changes in most of the mainland United States, Morocz explains, but it might be permitted in certain areas of Puerto Rico to combat widespread grid outages in the wake of Hurricane Maria.

Heila joined Greentown in December 2016 and has taken advantage of the incubator’s engineering software licenses, connections with investors, and general wealth of knowledge for startup leaders. Morocz also singles out Forge, a non-profit built by Greentown Labs to address crucial gaps for startups with physical products, as a critical resource Heila has utilized during its time at Greentown Labs. Forge’s Manufacturing Initiative connects startups with regional manufacturers and has supported Heila’s commercialization efforts.

“The Manufacturing Initiative has been very useful for us,” Morocz says. “Our first and second prototypes were built here by us in the machine lab, and then the folks at the Manufacturing Initiative were responsible for putting us in contact with the people that, today, we contract the work out to. So that has been key.”

Greentown Labs is a community of bold, passionate entrepreneurs creating solutions for today’s biggest climate and environmental challenges. Located in Somerville, Mass., the Greentown Labs Global Center for Cleantech Innovation is the largest cleantech incubator in North America, operating a 100,000 sq. ft. campus comprised of prototyping and wet lab space, shared office space, a machine shop, electronics lab, and a curated suite of programs and resources. Greentown Labs is home to more than 90 startups and has supported more than 210 since its inception.