Everyone knows the drill: you take the exit for a station, pull up to one of a dozen pumps, and fill your vehicle with fuel that was truck-delivered there.

That’s what putting gasoline in your car looks like. But the team at Ivys Energy Solutions doesn’t think that’s what filling up your fuel-cell electric vehicle needs to look like.

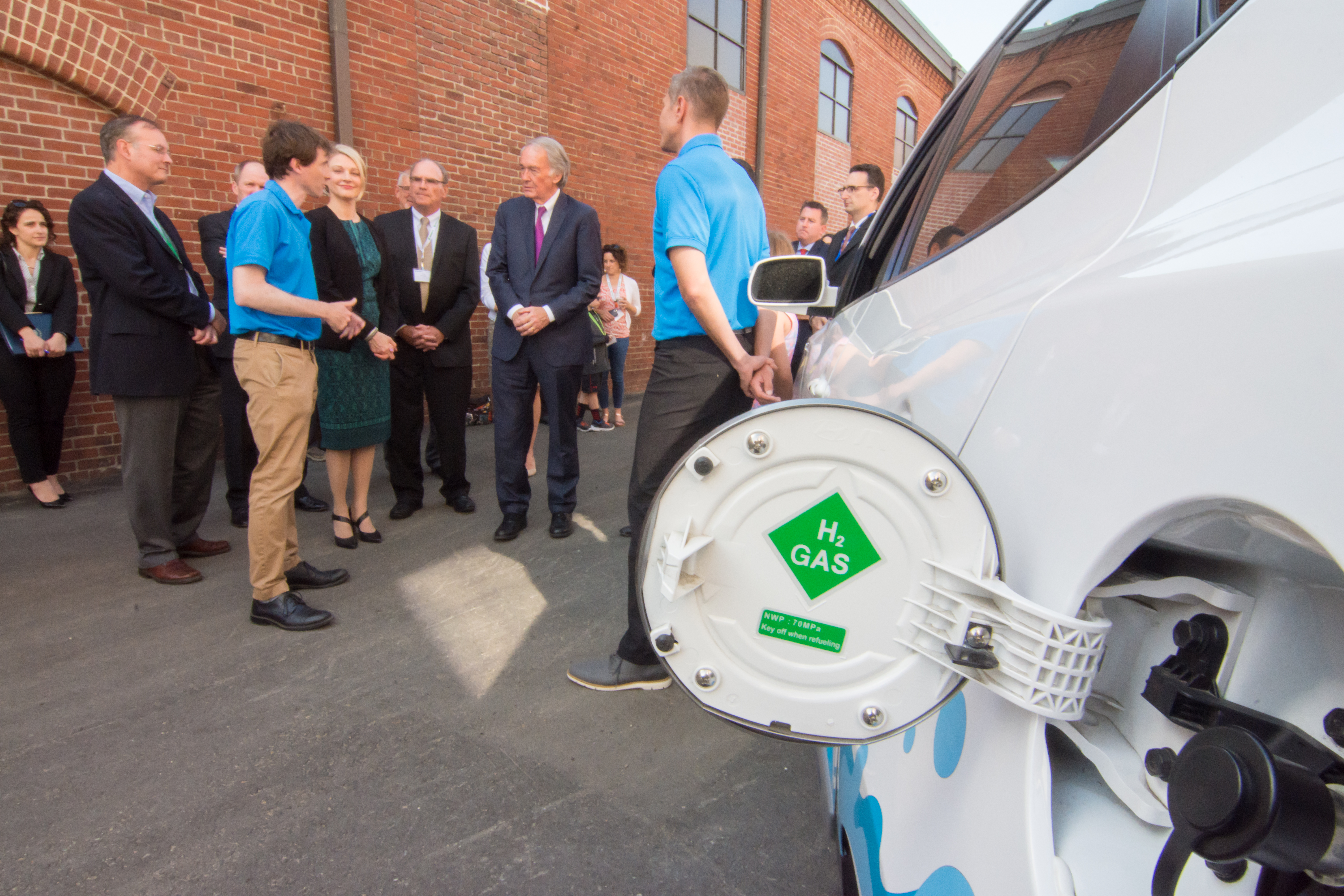

Fuel-cell electric vehicles (FCEVs) have electrochemical engines that split hydrogen and combine it with oxygen from the air, with water as the byproduct. FCEVs have two major advantages over battery-powered vehicles: they charge more quickly—think a few minutes rather than many hours—and are much lighter, which helps extend range.

“Here’s an electric vehicle that only makes water emissions,” says Darryl Pollica, CEO and co-founder of Ivys. “It’s a silent vehicle that can be filled up in three to five minutes. So that’s a completely different paradigm than taking an electric wire and charging a chemical battery onboard the vehicle.”

Like with battery-powered electric vehicles, infrastructure is a major concern in the adoption of FCEVs. The Ivys team explains that California, which is at the forefront of FCEV promotion and use in the United States, is tackling this problem by building hydrogen fueling stations that mimic gas stations.

“That’s one of the key differences about how we’re approaching this,” explains Ivys CTO Chris O’Brien. “So far, the development of the infrastructure has been, ‘All right, let’s just build the commercial network so that anybody can just go out and buy a hydrogen car, and they will be able to fill it up and drive it anywhere … and then wait for people to buy the cars.’”

Ivys’ approach is more distributed and focuses on the fleet model. Its SimpleFuel hydrogen refueling stations are compact and movable, which makes them easier, quicker, and far cheaper to install. The standalone stations also don’t need to have hydrogen trucked in—SimpleFuel stations are designed to fill 10 to 20 cars a day, so the hydrogen can be generated right inside the SimpleFuel station.

The SimpleFuel stations are ideal to help transition two use cases to FCEVs: captive fleets and tethered fleets. A captive fleet includes vehicles that don’t leave the premises, such as forklifts in a warehouse, while tethered fleets are vehicles such as delivery vans or municipal vehicles that return to a home base frequently. Given SimpleFuel’s small size, they’re also ideal for urban environments.

There’s precedent for new vehicle technologies getting started with fleets, according to O’Brien. Once FCEVs become widespread, SimpleFuel stations could supplement larger fueling spots that resemble today’s gas stations. But O’Brien and Pollica weren’t willing to wait for that day to help FCEVs get on roads and warehouse floors.

“We felt, having been in the industry for two decades, that this is what the industry needed to start moving the needle,” Pollica explains. “Because we’re so tired of waiting for this thing to come. The world needs this stuff now. We need a mix of EVs, whether it’s battery or fuel-cell EVs, so that’s why we formed Ivys back in 2014—to specifically address this need. The problem here is the infrastructure, and we have the knowledge and the know-how to approach this problem.”

Ivys has four projects in operation so far, including in an alley outside Greentown Labs and in a Toyota hydrogen car manufacturing plant in Japan to fuel FCEV forklifts. Toyota has significant interest in rolling out FCEVs and has become a repeat Ivys customer, according to Pollica and O’Brien.

Ivys has four projects in operation so far, including in an alley outside Greentown Labs and in a Toyota hydrogen car manufacturing plant in Japan to fuel FCEV forklifts. Toyota has significant interest in rolling out FCEVs and has become a repeat Ivys customer, according to Pollica and O’Brien.

The Ivys team is working with national and international organizations to adapt standards to support the SimpleFuel model. The SimpleFuel station next to Greentown will play a key role in this process, according to O’Brien.

“A lot of the testing to improve those international standards is going to happen here in the alley in the next month,” he says. “So this is going to have a global impact.”

O’Brien says Greentown was the right place to build a device like SimpleFuel, and recalls how Greentown CEO Emily Reichert and Somerville Mayor Joseph A. Curtatone gave Ivys their support for the alley station on the same day Ivys broached the idea.

“You need someplace like this, where people are more free to say, ‘Actually, why don’t we just take this opportunity to change the way we’ve been doing things for the last 100 years, because actually, this is a fundamentally new technology and it doesn’t need to follow the same model,’” O’Brien explains. “That’s been great for us, being able to have the launching pad here to be able to do this kind of stuff, the support of the other companies here who are doing similar things, and being able to lean on the Greentown staff.”

Greentown Labs is a community of bold, passionate entrepreneurs creating solutions for today’s biggest climate and environmental challenges. Located in Somerville, Mass., the Greentown Labs Global Center for Cleantech Innovation is the largest cleantech incubator in North America, operating a 100,000 sq. ft. campus comprised of prototyping and wet lab space, shared office space, a machine shop, electronics lab, and a curated suite of programs and resources. Greentown Labs is home to more than 90 startups and has supported more than 210 since its inception.