Batteries are a key technology for the energy transition, allowing for grid-scale storage of clean power, vehicle electrification, and more. So it’s no wonder that many scientists and entrepreneurs are working to create better batteries for widespread electrification and tech adoption.

Most battery innovations focus on the electrode materials—think silicon anodes, cobalt-free cathodes, or manganese-rich cathodes. But Greentown member Elementium Materials is taking a different approach: introducing a novel electrolyte that builds higher-energy-density, faster-charging, lower-cost, and longer-lasting batteries.

“We think 10,000 charge cycles is an ambition of the past,” Elementium Materials’s CEO Matthew Dawson says. “We’re seeing the ability to go much further than that.”

The electrolyte is what separates a battery’s anode and cathode, conducting ions from one end to the other when the battery discharges power. Traditionally, electrolytes use carbonates, which create side reactions that “consume valuable materials” and break down the battery, Dawson explains.

Crucially, Elementium Materials’s electrolyte has universal compatibility across electrode materials, meaning it can work with any battery technologies that arise in energy-transition innovations.

“The key to unlocking next-generation batteries is in the electrolyte,” Dawson says. “Our technology creates an incredibly stable battery that translates into very long calendar life, very long cycle life, higher voltage, and higher energy density. This could reshape the energy transition as we know it.”

Elementium Materials is not only improving the performance of batteries, but lowering their cost: by stretching batteries’ expensive electrode materials further, the innovation allows batteries to do more with less material. Its electrolytes are nonflammable and the electrolyte materials are recyclable.

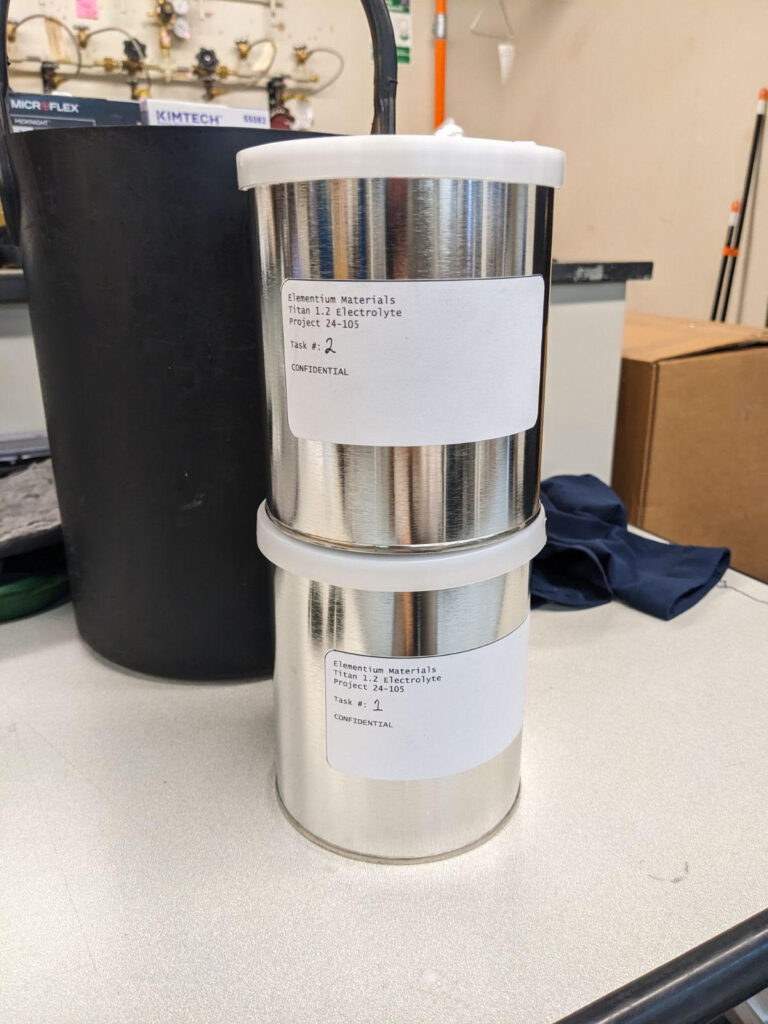

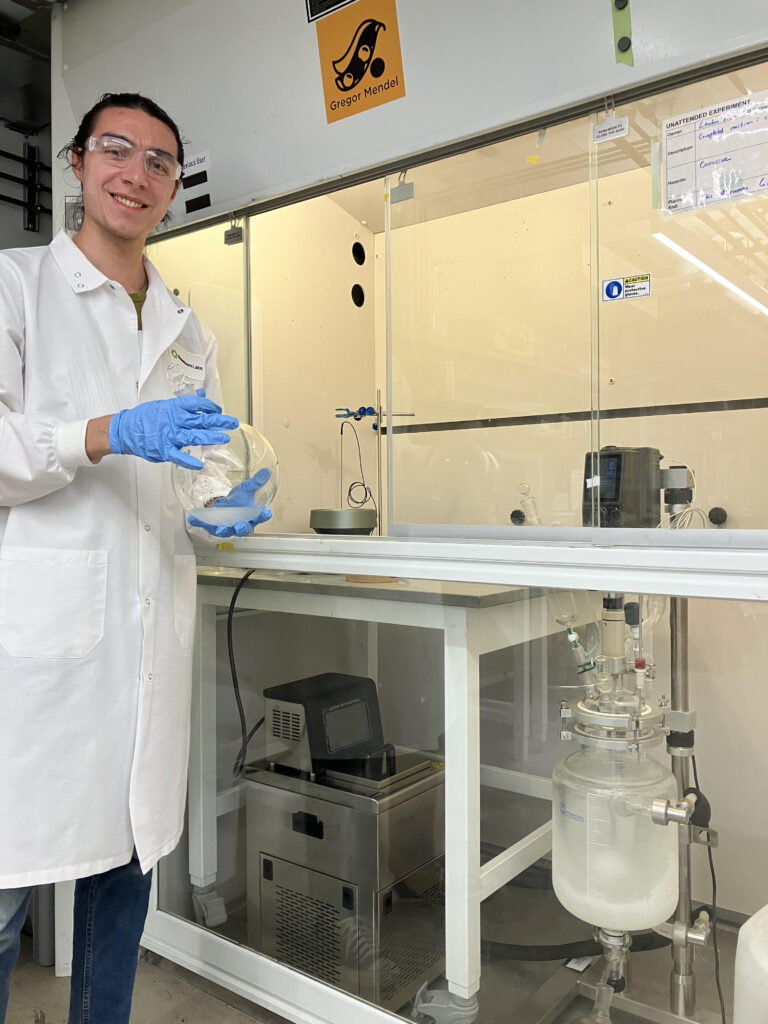

Elementium Materials moved into the wet lab at Greentown Boston in August 2024.

The startup is focusing on EVs, grid-scale storage, and consumer electronics, where its electrolyte can mean light-weighting EVs, increasing the lifetime of grid batteries, lowering prices for consumers, and more.

For Dawson—a serial entrepreneur who also spent 10 years working in energy technology at ExxonMobil and Equinor—the importance of high-caliber batteries became apparent during his 15 years living in Houston, TX, when he estimates he spent more than 30 days without power due to grid issues. He became interested in “stable, resilient, reliable backup battery power” and started looking for a technology to commercialize.

That search brought him to a former professor of his, Yang Shao-Horn, who was developing the novel electrolyte with Professors Jeremiah Johnson and Ju Li at MIT. The four co-founded Elementium Materials earlier this year.

The six-person, seed-stage company is quickly seeing success: Elementium Materials’ has launched more than a dozen EV qualification projects in recent weeks and plans to run up to 30 by year’s end. It was also recently named among the 10 most-promising energy tech startups at the Rice Alliance for Technology and Entrepreneurship’s annual Energy Tech Venture Forum.

“Because of Greentown, we were able to scale up our production process 100-fold and deliver our first customer sample in less than 30 days from joining Greentown and within 60 days of launching the company,” Dawson says, noting how his team was able to get started working in Greentown’s labs immediately after joining and has flexibly increased its lab footprint as the startup quickly grows. “This also allowed us to land six Fortune 500 customer trials within a month of getting funding and joining Greentown. What an acceleration Greentown enabled.”

Next year, the startup plans to fundraise and expand its team, and in 2026, it’s targeting a pilot-scale commercial plant and deployment in commercial consumer devices.

An engineer on Elementium’s team works in the wet lab at Greentown Boston.