Andrew Amigo came up with the idea for Blackburn Energy while sitting in traffic. As he watched a truck’s drive shaft spin, he realized he could harness its lost kinetic energy and convert it into renewable electricity.

“Everything clicked into place for me,” Amigo says. “Right there in my car I started taking notes, and started scratching out the idea of using the drive shaft and the wasted energy of the truck to create clean electricity, store it, and then reduce the amount of fossil fuels that the transportation industry has to burn.”

Trucks have an idling problem. Long-distance truckers spend 100 to 200 nights a year sleeping in their vehicles, and need the engine running to provide heat, air conditioning, or power to electronics. More than a billion gallons of diesel are used this way each year, according to Amigo—equivalent to almost 11 million tons of CO2.

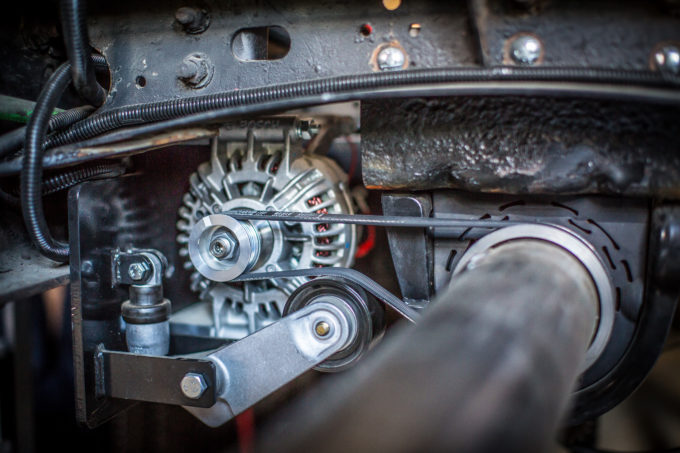

Blackburn’s technology generates renewable energy that can fuel electric auxiliary power units (APUs), eliminating the need to run engines overnight. The same system allows drivers to turn off their vehicles during deliveries while still operating the power lift gates.

Amigo sees Blackburn’s technology as an intermediary step to fully electric trucks.

“This is the beginning of an electrification revolution,” he says. “One day there will be electric trucks, but that day is pretty far away. For now, the goal is to electrify everything we can—we want to electrify everything on a diesel truck, including engine components, which will increase the fuel economy of the trucks in a pretty significant way.”

A key component to this stepping stone, Amigo emphasizes, is that the technology is widely accessible. Virtually any mechanic can install the system on virtually any large truck.

“We learned in customer discovery that it had to be available and accessible to the entire industry from the beginning,” Amigo says. “It cannot be what we call ‘trickle-down technology.’ We said, ‘We want to have something that is so inexpensive, so simple to use, that the people at the bottom of the pyramid can start using it right away, and not have to wait a decade for it to filter its way through the system to get to the average person.’”

The company can continue to electrify non-electric trucks bit by bit, according to Amigo. Blackburn also offers carbon credit reports to its users, which allow trucking companies to see—and show others, including their customers—how much clean energy they’re generating.

Blackburn is commercialized, and has a facility in Amesbury, Mass. in addition to its space at Greentown Labs. Throughout its road to commercialization, Amigo says Blackburn has taken advantage of the Manufacturing Initiative—run by FORGE, Greentown’s sister nonprofit.

“When you’re trying to cross from that R&D, prototype company into a commercial company, you have to attract a different group of people, and getting to them is hard,” Amigo explains. “A whole variety of people at Greentown have been unbelievable to us in opening doors and getting resources. When you’re the little guy, that’s such a big help.”

Greentown Labs is a community of bold, passionate entrepreneurs creating solutions for today’s biggest climate and environmental challenges. Located in Somerville, Mass., Greentown Labs is the largest cleantech incubator in North America, operating a 100,000 sq. ft. campus comprised of prototyping and wet lab space, shared office space, a machine shop, electronics lab, and a curated suite of programs and resources. Greentown Labs is home to more than 100 startups and has supported more than 230 since its inception.